Materials

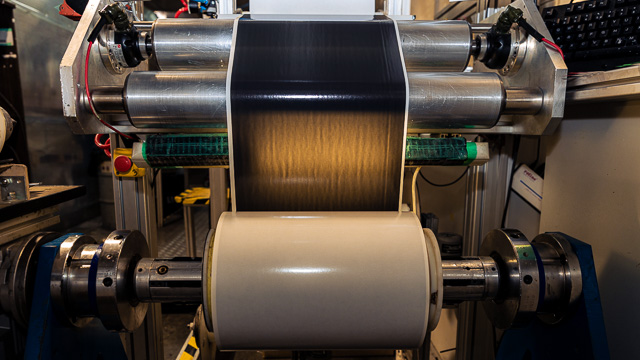

NTPT Adhesive films are advanced materials meticulously crafted for the bonding of composites. Consisting of a thin layer of resin, these films provide distinct advantages across a range of technical applications, including composite-composite bonding, composite-honeycomb bonding, composite-foam bonding, and composite-metal bonding.

Adhesive films play a pivotal role in composite molding, particularly when enhanced resin is required for superior impregnation. Composites, rich in fibers, gain significant advantages from these films, which effectively function as a filling agent at the regions where mold’s curvature can affect layers’ drapability. Resin films aid in avoiding the risk associated with porosities during challenging lamination situations.

Adhesive film

The AF367 epoxy based adhesive film is optimized for sandwich core bonding, especially honeycomb, and enables low-temperature curing. It is available in very low area weight, making your component even lighter.

If needed, resin film can also be manufactured from our prepreg resin systems to bond two composite parts using the same resin as in the composite itself.

01.

Heat and pressure activate the thin resin layer, ensuring a robust and uniform bond.

02.

The thin nature allows precise application, eliminating variations in adhesive distribution.

03.

Adhesive films contribute to lightweight solutions with excellent resistance to environmental factors.

04.

Compatible with various substrates, they find applications in diverse industries, enhancing adhesion in composite manufacturing.

The convenience of providing the adhesive film in a ‘combo,’ pre-deposited on the last layer of the preform, means it’s ready to use with no additional man-hours required. The adhesive films are specially designed to seamlessly co-cure with NTPT’s resins, ensuring compatibility and exhibiting excellent flowability during curing, especially in honeycomb structures.

Adresses

North Thin Ply Technology Sàrl

+41 21 811 08 88

Chem. du Closel 3

1020 Renens

CH – Switzerland

North Thin Ply Technology Sp. z o.o.

Pukowca 38A

44-240 Żory

PL – Poland

NTPT Ⓒ 2024. ALL RIGHTS RESERVED.

Join the NTPT community by registering for a bimontly meeting. Access the latest updates, articles, interviews and videos on cutting-edge composite materials for a wide range of industries.Don’t miss a thing – register now!

By subscribing to the NTPT newsletter, you consent to NTPT using your personal data for this purpose only. For more information, please visit our privacy policy page.